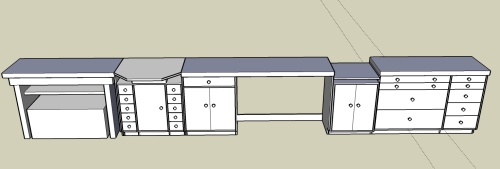

Not “green” in the environmental sense, mind you…but green in a very literal sense. I’ve spent literally months planning out most of the details of my new shop, since before they broke ground. One of the features I was most anxious to include that I was unable to have in my shared garage space was an honest-to-goodness central dust collection system. One of the earliest decisions I needed to make: metal or plastic?

Metal of Plastic?

I first read Sandor Nagyszalanczy’s oft recommended book “Woodshop Dust Control” where he makes a strong argument against the use of plastic PVC piping for ductwork citing the risk of explosions that could ruin your day/shop/life/etc. After reading this book it was clear to me that metal was the only way to go. That was, until I began researching actually purchasing the stuff. Expensive. What’s more, the stuff they sell at the “Big Box” stores is too thin…so the only real way to do this with metal ducting, beyond finding a local supplier (which I was unable to do) is to meticulously plot out the whole thing and place one big order to have shipped to the shop. While I’m no stranger to meticulous planning, I’ve never setup a dust collection system before and was not 100% sure I could plot this out perfectly without actually attempting to fit some pieces together first. In fact, I was pretty darn certain that I couldn’t plan this out to the last screw in advance of ordering the materials. I just knew I’d get half-way done with the install and either change my mind or realize I needed some other type of fitting(s) to finish the job. Without a local supplier, I’d be forced to place an order — likely a small one — and incur additional shipping charges and delays. Time’s too much of a premium to lose an entire day because I can’t get what I need. This realization sent me searching for alternatives.

It didn’t take long for me to find some interesting forum discussions online…but the clincher for me was this extremely well-crafted article. The upshot of reading this article was that I was now certain that I would definitely use the cheaper/easier-to-find S&D PVC piping for my system. Fortunately or Un- I was now also paranoid about what I could appreciate was the most dangerous aspect of my dust collection system — a smoldering fire in a collection bag. (Mental note: daily emptying of the bags is a must. But I digress…)

A bit of searching locally initially indicated that my local “Big Box” stores carried only up to 4″ diameter piping. My basic math says that I’d really be better off using a minimum of 5″ ducting for the main run. As S&D pipes aren’t offered in 5″, I opted for the next size up…which, as I mentioned, I was unable to locate locally. That is, until an unrelated and rare trip to Menards where I discovered all the 6″ and 4″ fittings and pipe I would ever need. Excellent.

Goin’ Green

Menards stocks their PVC piping in an outdoor lumber yard. This meant that I placed an order off a sheet with a nice picture of white 6″ PVC pipe listed as ASTM 2729 S&D. When I got into the yard, however, the pipe was actually the green stuff..ASTM 3034/SDR35. The Menards product number on the sticker on the pipe and the label on the bin matched my receipt, so I’m not sure if there was a mistake in their inventory or their labeling…or if they for some reason sell the 3034 and 2729 interchangably (seems unlikely), but I didn’t see the 2729 anywhere so I figured I’d use the somewhat heavier, green 3034 that I had paid for rather than start the hunt over again. I purchased a few 10′ lengths of the 4″ thin white stuff from Lowes as well figuring I’d at least have white drops.

Menards stocks their PVC piping in an outdoor lumber yard. This meant that I placed an order off a sheet with a nice picture of white 6″ PVC pipe listed as ASTM 2729 S&D. When I got into the yard, however, the pipe was actually the green stuff..ASTM 3034/SDR35. The Menards product number on the sticker on the pipe and the label on the bin matched my receipt, so I’m not sure if there was a mistake in their inventory or their labeling…or if they for some reason sell the 3034 and 2729 interchangably (seems unlikely), but I didn’t see the 2729 anywhere so I figured I’d use the somewhat heavier, green 3034 that I had paid for rather than start the hunt over again. I purchased a few 10′ lengths of the 4″ thin white stuff from Lowes as well figuring I’d at least have white drops.

Fittings

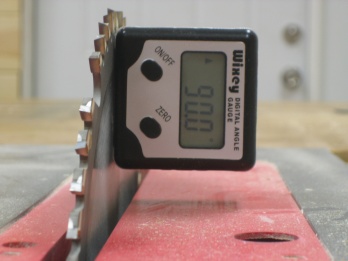

I purchased my blast gates and quick disconnect fittings from my local Woodcraft store and started the assembly. What I discovered during the assembly was that the thicker-walled SDR35 was a significantly snugger fit for the pipe fittings. Also, while a special coupling is required to attach the blast gates to 2729, they fit perfectly in the green stuff. So, while the 2729 is a bit cheaper and much lighter, I save money overall with the SDR35 since there are no adapters needed to fit the blast gates to the pipes. Serendipity.

Assembly continues apace. I’m currently roughly 50% complete with the core installation, that is the main 6″ line is 80% complete and half the drops are essentially in. I still need to build the hoods for the RAS and CMS and work out the details of the fittings for the router table, which will likely take more time than the assembly time to date. I’ve still got the two cameras capturing the process and have been sure to move them as needed as there’s no one position that can capture even most of the shop. Editing of the time-lapse is ongoing and I will be posting the completed video when the job is done, natch.